Magnetic extraction technique exhibits a notably proficient method for processing a diverse variety of components. This approach utilizes the natural magnetic characteristics of certain elements to selectively separate them from their non-magnetic comparisons. By deploying a intense magnetic field, ferromagnetic fragments are attracted towards the magnetic source, granting their removal from the remaining mixture.

- This approach finds broad applications in various industries, such as mining, waste management, and food processing.

- As well, magnetic separation offers several upsides over other separation techniques, including high precision and low footprint.

Iron Purification Solutions: Increasing Productivity via Magnetic Means

Amid industrial fluid processing and various production stages, removing iron from flowing materials is crucial to support product consistency and defend hardware. Traditional techniques for iron removal can be cost-intensive and high-energy. Magnetic separators offer a competent alternative, capitalizing on the magnetic properties of iron oxides to effectively extract iron from water or other solutions. By strategically incorporating magnetic separators into existing systems, industries can boost their functionality while reducing operational costs.

- Separation devices

- Capture iron substances

- Elevate capability

These compact units can be incorporated into a wide range of operations, supplying significant advantages over conventional iron removal techniques.

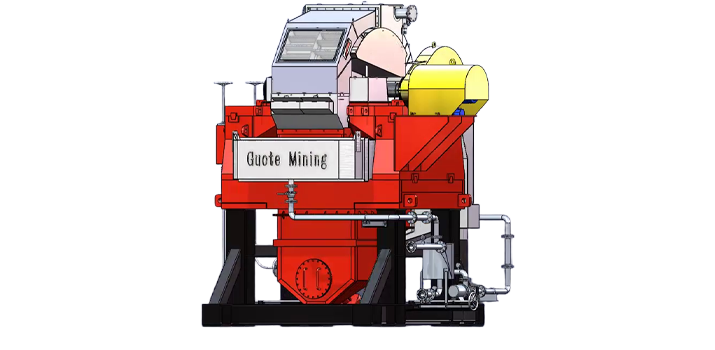

High-Power Wet Magnetic Filter

Throughout industrial purification fields, wet high intensity magnetic separators stand as powerful instruments, delivering precise and efficient separation of ferromagnetic elements from complex suspensions. These innovative systems harness the potent force of magnetism to effectively collect desired particles, resulting in enhanced product purity and process efficiency. The wet nature of the separation system allows for thorough cleaning and agitation, ensuring optimal performance and minimizing defilement. Wet high intensity magnetic separators find widespread utilization across diverse industries, including mining, food processing, pharmaceuticals, and wastewater treatment.

- By leveraging the principles of magnetism, these separators achieve remarkable separation proficiency

- Incorporating a wet separation process ensures thorough cleaning and agitation

- Wet high intensity magnetic separators are paramount for maintaining product purity across various industries.

Belt Type Magnetic Separators: Continuous and Reliable Iron Removal

Across numerous industrial uses, the robust removal of iron contaminants is paramount. Belt type magnetic separators provide an ideal solution, offering continuous operation and extraordinary performance. These systems utilize powerful permanent magnets strategically placed within a conveyor belt, effectively attracting and separating ferrous materials from the product stream. The moving belt ensures a constant flow of material, enabling uninterrupted extraction throughout the process.

- Belt type magnetic separators are highly adaptable to various industries, including mining, agriculture, food processing, and recycling.

- Their robust construction and simple design ensure lastingness, minimizing maintenance requirements and downtime.

- By integrating seamlessly into existing production lines, these separators offer a cost-effective means of maintaining product quality and boosting process efficiency.

With their robust magnetic capabilities and continuous operation, belt type magnetic separators are an indispensable tool for achieving consistent iron removal in diverse industrial settings. By effectively removing ferrous contaminants, these systems contribute to product purity, equipment protection, and overall operational excellence.

Uses of Magnetic Separators across Industrial Workflows

Magnetic separators exercise a wide range of applications in various industrial processes. These separators are instrumental in isolating ferrous metals from non-metallic materials, upgrading product quality and reducing contamination. In the mining industry, magnetic separators recover valuable iron ore from scrap. In food processing, they extract metal fragments from basic elements, ensuring consumer safety. Similarly, in wastewater treatment, magnetic separators are applied to secure ferrous metals from effluent streams, protecting aquatic life and ensuring water purity.

Magnetic Processes for Waste Recycling

Magnetic separation acts as a vital practice in waste management. This approach makes use of the magnetic properties of certain materials to efficiently separate them from non-magnetic waste streams. By using strong magnetic fields, ferrous metals like iron and steel can be magnetized away from avariety of materials, permitting their reinstatement.

The strengths of magnetic separation are abundant. It lowers landfill waste by retrieving valuable metals for reutilization. Additionally, it raises the overall effectiveness of waste sorting facilities. Magnetic separation also supports to a more ecological approach to waste management by diminishing environmental impact and conserving natural resources.

Deciding on the Right Magnetic Separator for Your Needs

Implementing a separation system can be an efficient way to separate ferrous materials from your product mix. However, with a variety of options available on the market, identifying the right one for your specific needs can seem daunting.

To ensure you obtain the most suitable magnetic separator, scrutinize factors such as the sort of materials you need to separate, the output of your process, and the anticipated scope of isolation.

- Varieties of magnetic separators encompass drum separators, plate separators, and suspended magnets. Each type provides unique advantages and is adapted for different applications.

- Understanding the potency of the magnetic field required for your application is crucial. A improved magnet can productively remove smaller particles, while a diminished magnet may be adequate for larger materials.

- Surveying different manufacturers and weighing their products can help you identify the best option for your prerequisites.

Appreciating Magnetic Field Strength and Separation Performance

Magnetic field strength plays a fundamental role in the efficiency of separation processes. A stronger magnetic field exerts a elevated force on ferromagnetic materials, enabling them to be productively removed from non-magnetic substances. Multiple factors influence the strength of the magnetic field, including the type and number of magnets used, their placement, and the distance between them. Optimizing these parameters is crucial for achieving high separation capability.

The separation success is strongly correlated with the strength of the magnetic field. Augmented magnetic fields result in a stronger force exerted on ferromagnetic materials, leading to improved separation. However, it's important to note that excessive magnetic field strength can lead to detrimental effects, such as increased energy consumption and potential damage to the particles being separated.

Moreover, factors such as particle size, shape, and magnetism-based properties can also alter separation performance.

Understanding the relationship between magnetic field strength and separation ability is essential for designing and operating effective magnetic separation systems.

Next-Generation Magnetic Separator Technology: Innovations in Material Processing

The realm of material processing has witnessed a significant transformation with the advent of advanced magnetic separator technology. These advanced systems employ potent magnetic fields to select target materials from complex mixtures with unprecedented effectiveness. Contemporary developments in material science and engineering have resulted in a wide range of separator designs, each optimized for unique applications.

Moreover, advancements in sensor technology and control algorithms have refined the performance and productivity of magnetic separators. This advancement has released new possibilities in various industries, including mining, circular economy, pharmaceuticals, and food processing.

- Consider,

- applying advanced magnetic gradient techniques to maximize iron extraction efficiency.

- Besides, superparamagnetic iron oxide nanoparticles are increasingly employed in biomedical applications for targeted drug delivery and magnetic resonance imaging.

Magnetic Separation Optimization: Maximizing Efficiency and Output

Optimizing magnetic separation processes offers a crucial step in achieving maximum effectiveness. By fine-tuning parameters such as magnetic field strength, particle size distribution, and flow rate, experts can significantly upgrade the separation efficiency and capacity of the process. Careful consideration of factors like material properties and operational conditions is essential for establishing the optimal parameters that minimize residual contamination and maximize product purity.

- Implementing advanced magnetic separation technologies, such as high-gradient magnetic separation (HGMS), can further advance separation capabilities by creating stronger magnetic fields and enabling efficient particle capture.

- Continuous monitoring and control of process parameters based on real-time data confirms consistent performance and increases overall system efficiency.

Troubleshooting Common Issues with Magnetic Separators

Magnetic separators are indispensable tools for many industries. However, like any piece of hardware, they can sometimes be subject to issues. We will explore some common problems and their expected solutions:

One frequent problem is weak magnetization. This can be caused by a variety of factors, covering age, improper fixing, or damage to the magnetic nucleus. Resolve this, you can try refurbishing the magnet, ensuring proper alignment and joining with the material being separated.

- In addition issue is dirt accumulation of the separator's chamber. This can be due to the aggregation of non-magnetic materials. Repeatedly cleaning the separator with a acceptable solvent or tool will help maintain its effectiveness.

- Too, the material being separated may not be highly magnetic. In this case, you may need to adjust the magnitude of the magnetic field or consider a different type of separator.

Magnetic sorting methodology validates a greatly capable approach for treating a diverse array of substances. This approach makes use of the inherent magnetic properties of certain items to precisely extract them from their non-magnetic counterparts. By exerting a forceful magnetic field, ferromagnetic compounds are magnetized towards the magnetic source, empowering their detachment from the remaining mixture.

- This process finds widespread applications in various domains, such as mining, waste management, and food processing.

- In addition, magnetic separation offers several assets over other separation techniques, including high specificity and low footprint.

Iron Purification Solutions: Increasing Productivity via Magnetic Means

Amid industrial fluid processing and various production stages, separating iron from liquid phases is necessary to support product consistency and defend hardware. Traditional procedures for iron removal can be resource-draining and fuel-consuming. Magnetic separators offer a efficient alternative, employing the magnetic properties of iron oxides to readily extract iron from water or other fluid compounds. By strategically incorporating magnetic separators into existing systems, industries can optimize their output while reducing operational financial burdens.

- Separation devices

- Capture iron substances

- Enhance process performance

These efficient units can be joined into a wide range of applications, delivering significant advantages over conventional iron removal techniques.

High-Power Wet Magnetic Filter

During industrial cleaning processes, wet high intensity magnetic separators stand as powerful mechanisms, offering precise and efficient separation of ferromagnetic components from complex blends. These innovative mechanisms harness the potent force of magnetism to effectively withdraw desired particles, resulting in enhanced product purity and process efficiency. The wet nature of the separation process allows for thorough cleaning and agitation, ensuring optimal performance and minimizing impurity. Wet high intensity magnetic separators find widespread implementation across diverse industries, including mining, food processing, pharmaceuticals, and wastewater treatment.

- By leveraging the principles of magnetism, these separators achieve remarkable separation capability

- Harnessing a wet separation process ensures thorough cleaning and agitation

- Wet high intensity magnetic separators are essential for maintaining product purity across various industries.

Dependable Iron Separation through Belt Systems

Within diverse industrial settings, the robust removal of iron contaminants is paramount. Belt type magnetic separators provide an ideal solution, offering continuous operation and superior performance. These systems utilize powerful permanent magnets strategically placed within a conveyor belt, effectively attracting and separating ferrous materials from the product stream. The moving belt ensures a constant flow of material, enabling uninterrupted segregation throughout the process.

- Belt type magnetic separators are highly adaptable to various industries, including mining, agriculture, food processing, and recycling.

- Their robust construction and simple design ensure resilience, minimizing maintenance requirements and downtime.

- By integrating seamlessly into existing production lines, these separators offer a cost-effective means of maintaining product quality and improving process efficiency.

With their exceptional magnetic capabilities and continuous operation, belt type magnetic separators are an indispensable tool for achieving consistent iron removal in diverse industrial settings. By effectively removing ferrous contaminants, these systems contribute to product purity, equipment protection, and overall operational excellence.

Utilizations of Magnetic Separators in Production

Magnetic separators exploit a wide range of applications in various industrial processes. These separators are instrumental in removing ferrous metals from non-metallic materials, boosting product quality and curtailing contamination. In the mining industry, magnetic separators gather valuable iron ore from residues. In food processing, they purge metal fragments from initial substances, ensuring consumer safety. Similarly, in wastewater treatment, magnetic separators are used to seize ferrous metals from effluent streams, protecting aquatic life and guarding water purity.

Magnetic Technology for Efficient Waste Control

Magnetic separation exists as a vital system in waste management. This framework employs the magnetic properties of certain materials to powerfully separate them from extra waste streams. By leveraging strong magnetic fields, ferrous metals like iron and steel can be magnetized away from adiversity of materials, allowing their retrieval.

The benefits of magnetic separation are numerous. It curtails landfill waste by reclaiming valuable metals for recovery. Additionally, it strengthens the overall capability of waste sorting facilities. Magnetic separation also supports to a more ecological approach to waste management by cutting down environmental impact and conserving natural resources.

Determining the Right Magnetic Separator for Your Needs

Implementing a sorting device can be an efficient way to extract ferrous materials from your goods flow. However, with a variety of types available on the market, picking the right one for your specific needs can seem complex.

To ensure you obtain the most best magnetic separator, review factors such as the kind of materials you need to isolate, the output of your process, and the expected quantity of filtering.

- Varieties of magnetic separators include drum separators, plate separators, and raised magnets. Each type offers differentiated advantages and is fitted for different applications.

- Understanding the degree of the magnetic field required for your application is crucial. A more potent magnet can effectively remove smaller particles, while a subdued magnet may be satisfactory for larger materials.

- Researching different manufacturers and contrasting their products can help you spot the best alternative for your criteria.

Appreciating Magnetic Field Strength and Separation Performance

Magnetic field strength plays a fundamental role in the efficiency of separation processes. A stronger magnetic field exerts a higher force on ferromagnetic materials, enabling them to be capably removed from non-magnetic substances. A variety of factors influence the strength of the magnetic field, including the type and number of magnets used, their disposition, and the distance between them. Optimizing these parameters is crucial for achieving high separation capability.

The separation performance is immediately correlated with the strength of the magnetic field. Elevated magnetic fields result in a more force exerted on ferromagnetic materials, leading to improved separation. However, it's important to note that excessive magnetic field strength can lead to negative effects, such as increased energy consumption and potential damage to the elements being separated.

Besides, factors such as particle size, shape, and magnetic properties can also affect separation performance.

Understanding the relationship between magnetic field strength and separation capacity is essential for designing and operating effective magnetic separation systems.

Revolutionary Magnetic Separator Technology: Innovations in Material Processing

The realm of material processing undergoes a significant transformation with the advent of advanced magnetic separator technology. These modern systems employ intense magnetic fields to segregate target materials from complex mixtures with unprecedented reliability. Contemporary developments in material science and engineering have spawned a multifaceted range of separator designs, each optimized for exclusive applications.

Besides, advancements in sensor technology and control algorithms have upgraded the performance and productivity of magnetic separators. This enhancement has facilitated new possibilities in various industries, including mining, material reclamation, pharmaceuticals, and food processing.

- Consider,

- deploying high-gradient magnetic extraction in iron ore plants to attain superior iron extraction rates.

- On the other hand, superparamagnetic iron oxide nanoparticles are increasingly employed in biomedical applications for targeted drug delivery and magnetic resonance imaging.

Magnetic Separation Optimization: Maximizing Efficiency and Output

Optimizing magnetic separation processes stands as a crucial step in achieving maximum efficiency. By fine-tuning parameters such as magnetic field strength, particle size distribution, and flow rate, practitioners can significantly amplify the separation efficiency and results of the process. Careful consideration of factors like material properties and operational conditions is essential for selecting the optimal parameters that cut residual contamination and magnetic separator maximize product purity.

- Implementing advanced magnetic separation technologies, such as high-gradient magnetic separation (HGMS), can further increase separation capabilities by creating stronger magnetic fields and facilitating efficient particle capture.

- Continuous monitoring and regulation of process parameters based on real-time data guarantees consistent performance and augments overall system efficiency.

Troubleshooting Common Issues with Magnetic Separators

Magnetic separators are indispensable tools for countless industries. However, like any piece of technology, they can sometimes be subject to issues. Now we explore some common problems and their probable solutions:

One frequent trouble is poor magnetization. This can be caused by a range of factors, covering age, improper mounting, or damage to the magnetic component. Fix this, you can try refurbishing the magnet, ensuring proper alignment and linkage with the material being separated.

- Next issue is adulteration of the separator's surface. This can be due to the collection of non-magnetic materials. Regularly cleaning the separator with a acceptable solvent or tool will help maintain its functionality.

- As well, the material being separated may not be effectively magnetic. In this case, you may need to adjust the intensity of the magnetic field or consider a different type of separator.