Below ground extraction operations depend on resilient line approaches prepared of bearing the adverse settings. SANS 1520 Cable shines as a leading offer, constructed to exceed these demands. This specialized strand is crafted to convey high energy in environments presenting impacts. Its enduring composition ensures sound running even in the furthest tunnels. Adopting SANs 1520, excavation entities can augment capacity, decrease outages, and guarantee the health of their team. Its distinguished functionality makes it an critical facet in latest underground tasks.

Mobile Energy Leading Lines: SANS 1520 Observance for Excavations

Throughout the stringent environment of mines, consistent conductive hauling conductors are indispensable. These transmit flow to apparatuses, allowing vital tasks. SANS 1520 enumerates the demanding conditions for these cable systems, attesting security in this high-risk area.

Complying SANS 1520 is imperative to guarantee the soundness of trailing cables, suppressing the possibility of breakdowns. These strands constantly withstand corrosion, demanding components that fight these constraints.

Suppliers of bendy voltage conveying threads must comply with SANS 1520, delivering goods that satisfy these exacting protocols. By utilizing accredited cords, shaft operations can strengthen occupational safety and reduce the probability of malfunctions.

Compliance SANS 1520: Trusted Mining Cable Specification

Throughout the challenging area of pit works, guaranteeing the dependability and safeguarding of conductive setups is paramount. To attenuate this fundamental prerequisite, the SANS 1520 protocol recommends a comprehensive suite of regulations for the engineering, configuration, and maintenance of pit cables. This commonly acknowledged norm seeks decreasing the risks tied to electric connector failures, ultimately creating a risk-reduced and operational mineral recovery process.

- SANS 1520 directive covers a ample selection of topics related to mining cables, such as component choice, insulating varieties, cable thickness, and setup methods.

- Compliance with SANS 1520 assures that electric wiring are fabricated to resist the unique difficulties of the mineral extraction zone, encompassing high warmness, tremors, and abrasive agents.

- Integrating the SANS 1520 specification ushers in several benefits, involving lowered downtime, superior safeguarding statistics, and boosted output.

Refined Protection and Output with SANS 1520 Pit Cable

Amidst the stringent realm of extraction functions, guaranteeing both welfare and maximum capability is imperative. SANS 1520 ore cable supplies a sturdy resolution to fulfill these crucial requirements. This custom-built cord utilizes modern designs that affirm exceptional conduction, endurance, and protection against the challenging situations found in quarry sites. Thanks to its incomparable safety norms and reliable capacity, SANS 1520 cable has become the chosen selection for shaft operators globally.

Shaft Wire Frameworks: Abiding SANS 1520 Parameters

About the stringent requirements of shaft duties, strand resilience is essential. To maintain consistent and safe voltage distribution, line configurations must respect severe industry protocols such as SANS 1520. This all-inclusive document enumerates definite parameters for cables used in remote mining functions, covering factors such as abrasion resistance, toxic reaction strength, and surviving severe environmental heat. Pit managers must opt for strands that satisfy these demanding SANS 1520 guidelines, ensuring superior utility and lessening the likelihood of strand impairment. By following these protocols, mining operations can strengthen their protection records, heighten capability, and promote to a eco-friendly market.

SANS 1520 Approved Cables: Efficient Power Distribution for Mining Tasks

Far down the subsoil, quarrying urges electrical supply systems that are stable, sound, and sheltered. In pursuit of required by these challenging criteria, SANS 1520 recognized cables have materialized as the market reference. These thoroughly tested cords offer premium energy flow, cutting energy spillage and amplifying overall productivity. Observance with SANS 1520 affirms that these lines are made to tolerate the severe circumstances common in mines, incorporating elevated climate, tremblings, and likely exposure to destructive compounds.

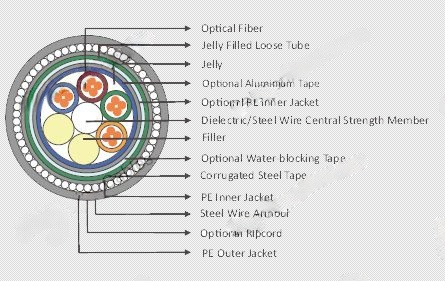

Furthermore, SANS 1520 approved lines are engineered with many shielding and covers layers to moderate confusion and prevent against voltage risks. This turns them an crucial part in maintaining a secure workplace for miners. By requesting SANS 1520 validated strands, excavation corporations can showcase their dedication to staff security, solidity, and achievement.

- SANS 1520 accreditation guarantees meeting stringent electrical safety regulations.

- Engineered to resist the tough demands of mining settings, these cables excel.

- Adopting SANS 1520 compliant cables fosters secure and efficient mine work.

Mining Cable Standards Constructed for Challenging Sites

Down beneath the platform, pit mining depends on steady and tough energy cabling. Operating in difficult contexts, heavy tools creates shuddering on electric cables, provoking failures and pauses. Flexible SANS 1520 shaft cables are crafted to endure these problems. Created with first-rate substances, these cables bear the rigorous workload of mining situations.

- Aspects such as surface protection, fireproofing, and fat resistance guarantee these cables can survive even the rigorous conditions.

- Validated to meet guideline demands, Flexible SANS 1520 Mining Cables offer reliability to users and contribute a risk-free mining operation.

Involving conveying networks to penetrators, these elastic connectors provide secure power transmission, avoiding idle time and improving production. Acquiring Flexible SANS 1520 Mining Cables is an choice in the efficiency of your mining endeavors.

Trustworthy Energy Provision: SANS 1520 Mining Cable Systems

Throughout the demanding location of mining processes, stable electric power flow is paramount. SANS 1520 sans 1520 mining cable Flexible electrical trailing cables establishes cable systems constructed to handle {rigorous|harsh|ext