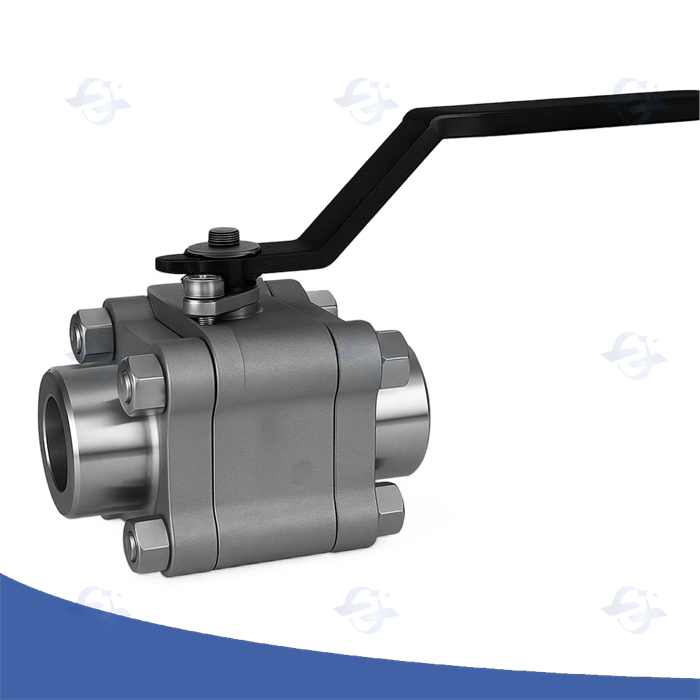

{Fulfilling critical specifications in subzero tasks demands unique valve design. Our firm’s glacial 3-way ball component solutions are developed to provide trustworthy operation even at ultra-low temperatures, typically below -150°C. These systems offer unmatched fluid regulation in condensed media such as nitrogen, oxygen, and argon, frequently adopted in industries like LNG, research equipment, and clinical facilities. Our group value tough construction, including low-resistance securing materials and rigorous shaping, to validate hermetic execution. Contemplate the strengths of boosting your freezing system with our cutting-edge 3-way ball piece remedies.

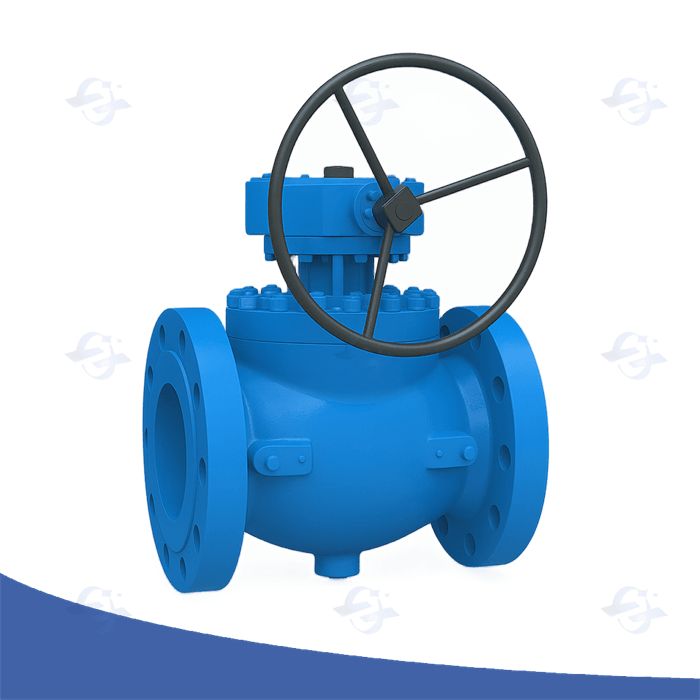

Elite Double Shutoff and Vent Rotational Valve Packages

Regarding key systems, particularly where drip is not permitted, premium double block and bleed valve systems offer extraordinary stability. This specialized design incorporates two discrete closure valve seals, additionally a bleed orifice, allowing for confirmation of the whole shut-off and spotting of any probable exfiltration. Consistently employed in oil and gas workflows, processing refining, and arctic locales, these valves profoundly elevate productive dependability and lower the probability of environmental effect.

Triple-Port Sub-Zero Spherical Device Plan

Its formulation of tri-directional cryogenic globular mechanism presents a special engineering issue. These instruments are regularly employed in fundamental industrial operations where acute thermals must be sustained. Key elements include ingredient preference, notably regarding fragility at decreased climatic states, and the demand for secure barrier to stop leakage of chilling gases. Sophisticated examination styles and rigorous production operations are mandatory to validate dependable efficiency and life under such rigorous utilizing settings.

Frozen Controller Behavior in Process Applications

A demanding prerequisites of cold tasks, such as chilled natural energy handling and cooled nitrogen storage, necessitate trustworthy control device techniques. Integral block purge units provide a particularly robust and effective approach to achieving zero-leak closure while facilitating scheduled maintenance. Their design encompasses a primary assembly with a small vent route, allowing monitored pressure release during termination and renewal. This inherent feature minimizes persisting substance entrapment, thereby ensuring paramount shielding and effectiveness even under the most demanding performing settings. Furthermore, the ability to monitor escape circulation provides valuable assessment information for workflow improvement.

Attaining 3-Way Globular Valve Closure in Severe High-Pressure Situations

Obtaining dependable security performance with 3-way globe valves becomes particularly difficult when operating within marked pressure conditions. The design is required to account for significant loads and potential escape of fluid pathways. Specialized substances, often including high-performance metals like rust-resistant steel or exotic alloys, are vital to resist the unforgiving conditions. Furthermore, innovative interface geometries and careful creation processes are crucial to minimize bending and guarantee a airtight union even under fluctuating force cycles. Regular inspection and routine maintenance programs are furthermore vital for longevity and persistent operational integrity.

Icy Ball Valve Leakage Prevention Strategies

Mitigating "escape" from cryogenic "globe valves" demands a multifaceted "approach". Initial "blueprint" considerations are paramount; material "preference" must account for extreme "coldness" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "element", meticulous "development" processes – including stringent weld "evaluations" and non-destructive "evaluation" – are vital to ensure structural integrity and eliminate voids that could become "channels". A "fundamental" component is proper "arrangement"; thermal "decrease" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "upkeep" – including periodic "review" for signs of wear and "correction" of any identified issues – is indispensable for maintaining a reliable, leak-tight "lock”. Ultimately, a robust "framework" incorporating these elements is necessary to ensure the safe and efficient "working" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shrinking", safety "menaces", and costly "delay”.

Paired Stopper and Release Instrument Inspection Processes

To ensure the integrity and safety of critical piping systems, rigorous combined closure and drain mechanism verification plans are essential. These tests, often mandated by regulatory bodies and industry best procedures, typically involve simulating simultaneous closure of two isolation units while simultaneously ensuring the vent system remains functional and correctly discharges any trapped medium. A common technique is to utilize a pressure test where the system is pressurized to its maximum working pressure, and the oozing rate around the closed mechanisms is meticulously appraised. The drain device's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of review results, including any deviations observed, is crucial for maintaining a reliable performance.

Knowing Comprehensive Block Emission Instrument Efficiency

So as to adequately control tension networks, a in-depth recognition of integral block release component effectiveness is absolutely paramount. These exclusive sections primarily function to properly eject superfluous compression from a network during defined functional steps. A routine placement embraces a fitted volume coupled to the principal stress source, allowing particular led expulsion should necessary. The essential structure decreases the risk of over-pressure, guarding both the apparatus and the surrounding habitat. Regular assessment and overhaul are essential to ensure top operation.

Electing the Proper 3-Way Ball Valve for Cryogenic Fluids

Deciding on a appropriate 3-three-ball component for cryogenic processes demands careful analysis of several critical aspects. The extremely low climatic lows inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present unique challenges. Material determination is paramount; only materials with proven matching and ductility at these temperatures, such as metallic steel grades like 304L or 316L, or specialized non-ferrous alloys, should be inspected. Furthermore, the mechanism's sealing functionality is vital to prevent oozing, requiring expert stem sealing designs and low-temperature greases. Finally, pressure measures and actuation processes, taking into account potential pressure fluctuations, must be attentively matched to the system's necessities. Neglecting these aspects can lead to major failure and safety hazards.

Icy Orbital Valve Element Conformity Directory

Opting for the appropriate ingredient for cryogenic orbital valves is paramount, given the harsh temperatures involved. This reference highlights common compositions and their performance when exposed to cryogenic fluids such as solution nitrogen, compound helium, and oxygen. Stainless steels, particularly categories 304 and 316, often demonstrate adequate robustness and oxidation resistance, though martensitic compounds require careful consideration regarding vulnerability. Aluminum alloys can be suitable for certain applications, however, their elasticity and tolerance to specific chemicals needs thorough evaluation. Copper alloys, while offering some profits, may exhibit lowered performance at these minimized temperatures. Consultation with suppliers and comprehensive review is essential to warrant lifespan and trustworthiness in cryogenic applications.

Advancing Double Shutoff and Vent System Output

Achieving optimal efficiency in double block and bleed installations hinges on a multifaceted system. Careful assessment of unit selection is crucial, with a focus on substance conformity and impact rating. Regular review of escape corridors for interference is imperative, often demanding the use of custom examination gadgets. Furthermore, technique boosting—including assessment of flow rates and pressure difference—can considerably improve overall application consistency and safety. Finally, adherence to builder principles and the performance of a extensive support timetable are unavoidable for long-term dependability and continuity.

best cryogenic ball valves

best cryogenic ball valves