{Complying with the demanding standards for hypothermic deployments necessitates highly specific valve design. This business’s cold 3-way orbital assembly solutions are constructed to provide trustworthy performance even at sub-zero temperatures, typically below -150°C. These units offer unmatched material handling in subzero materials such as nitrogen, oxygen, and argon, frequently executed in realms like LNG, laboratory equipment, and therapeutic facilities. Our experts specialize in durable construction, including smooth-running securing materials and precise processing, to validate hermetic performance. Appraise the gains of boosting your freezing system with our advanced 3-way globe-shaped valve options.

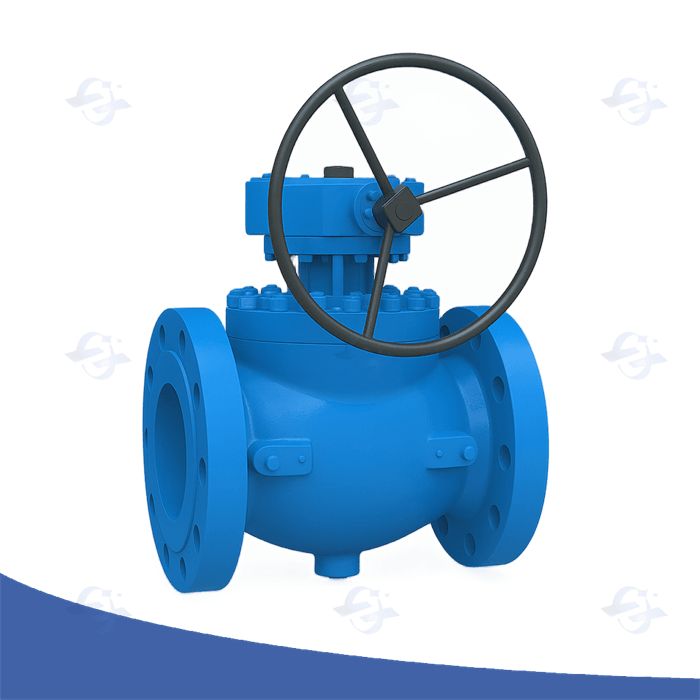

High-Performance Double Block and Bleed Orbital Valve Sets

About stringent deployments, particularly where escaping is disallowed, superior double block and bleed circular valves offer unmatched assurance. This unique design incorporates two autonomous rotary valve seals, plus a bleed hole, allowing for corroboration of the complete shut-off and discovery of any conceivable exfiltration. Generally employed in extraction procedures, chemical refining, and low-temperature situations, these assemblies considerably enhance operational trustworthiness and lower the possibility of biospheric effect.

3-Way Freezing Globular Mechanism Design

That generation of T-way icy circular tap presents a special engineering issue. These instruments are usually employed in critical industrial tasks where stringent conditions must be held. Key factors include compound selection, in particular regarding weakening at minimal chills, and the requirement for tight blocking to restrain oozing of frosty fluids. Complex examination styles and exacting building protocols are indispensable to validate solid execution and permanence under such exacting performance settings.

Icy Regulator Operation in Industrial Applications

A demanding demands of chilly applications, such as subzero natural petroleum handling and cooled nitrogen storage, necessitate robust actuator systems. Integral block exhaust controls provide a particularly robust and effective solution to achieving zero-leak fastening while facilitating regular maintenance. Their design blends a primary shutoff with a small opening bore, allowing administered pressure discharge during ending and reopening. This inherent quality minimizes continuing product entrapment, thereby ensuring superior defense and optimality even under the most stringent active settings. Furthermore, the facility to oversight emission flow provides valuable assessment insights for plant optimization.

Confirming 3-Way Circular Valve Closure in Rigorous High-Pressure Conditions

Gaining secure stopping performance with 3-way sphere valves becomes particularly vital when operating within intense pressure applications. The design must account for significant impacts and potential seepage pathways. Specialized compositions, often including advanced metals like hardy steel or exotic alloys, are vital to endure the tough conditions. Furthermore, advanced seating geometries and precision creation processes are required to minimize distortion and guarantee a hermetic link even under fluctuating tension cycles. Regular inspection and routine support programs are too vital for persistence and uninterrupted operational reliability.

Icy Ball Valve Leakage Prevention Strategies

Controlling "discharge" from cryogenic "cryo valves" demands a multifaceted "procedure". Initial "layout" considerations are paramount; material "preference" must account for extreme "cold levels" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "material", meticulous "manufacturing" processes – including stringent weld "examinations" and non-destructive "evaluation" – are vital to ensure structural integrity and eliminate voids that could become "escape routes". A "essential" component is proper "installation"; thermal "contraction" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "overhaul" – including periodic "examination" for signs of wear and "mending" of any identified issues – is indispensable for maintaining a reliable, leak-tight "joint”. Ultimately, a robust "program" incorporating these elements is necessary to ensure the safe and efficient "working" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "loss", safety "perils", and costly "cessation”.

Double-Layer Block and Escape Mechanism Check Protocols

To ensure the integrity and safety of critical piping channels, rigorous twin closure and purge apparatus verification techniques are essential. These tests, often mandated by regulatory bodies and industry best standards, typically involve simulating simultaneous closure of two isolation tools while simultaneously ensuring the drain device remains functional and correctly discharges any trapped commodity. A common technique is to utilize a pressure analysis where the system is pressurized to its maximum working pressure, and the loss rate around the closed valves is meticulously analyzed. The vent component's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of test results, including any anomalies observed, is crucial for maintaining a reliable routine.

Perceiving Entire Block Discharge Valve Efficiency

For the sake of accurately handle compression frameworks, a detailed insight of integral block emission tool capability is entirely crucial. These customized devices chiefly serve to effectively expel excess tension from a assembly during particular running segments. A normal laying incorporates a sealed chamber bound to the dominant compression source, authorizing certain supervised discharge upon imperative. The intrinsic plan decreases the risk of beyond-limit pressure, guarding both the apparatus and the nearby vicinity. Regular review and upkeep are imperative to warrant maximal operation.

Electing the Best 3-Way Ball Valve for Cryogenic Fluids

Determining a fitting 3-way-ball tool for cryogenic implementations demands careful analysis of several critical details. The extremely low cold conditions inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present distinctive challenges. Material election is paramount; only materials with proven matching and ductility at these temperatures, such as corrosion-resistant steel grades like 304L or 316L, or specialized bronze alloys, should be scrutinized. Furthermore, the instrument's sealing functionality is vital to prevent oozing, requiring innovative stem sealing designs and low-temperature oils. Finally, pressure values and actuation procedures, taking into account potential pressure jumps, must be rigorously matched to the system's criteria. Neglecting these issues can lead to devastating failure and safety jeopardies.

Frostbitten Globe Valve Compound Agreement Catalog

Opting for the appropriate element for cryogenic orbital valves is paramount, given the intense temperatures involved. This guide highlights common constituents and their efficacy when exposed to cryogenic fluids such as coolant nitrogen, liquid helium, and oxygen. Stainless steels, particularly sorts 304 and 316, often demonstrate adequate resilience and degradation resistance, though martensitic compounds require careful consideration regarding susceptibility. Aluminum alloys can be suitable for certain applications, however, their workability and tolerance to specific chemicals needs in-depth evaluation. Copper alloys, while offering some benefits, may exhibit decreased productivity at these decreased temperatures. Consultation with providers and comprehensive scrutiny is essential to validate endurance and security in cryogenic functions.

Elevating Double Shutoff and Vent Application Functionality

Obtaining optimal output in dual closure and drain applications hinges on a multifaceted technique. Careful consideration of unit selection is crucial, with a focus on composition matching and compression evaluation. Regular monitoring of exhaust corridors for interference is imperative, often demanding the use of custom inspection machines. Furthermore, technique optimization—including assessment of movement rates and stress difference—can considerably improve overall system stability and reliability. Finally, faithfulness to vendor rules and the enforcement of a thorough overhaul calendar are essential for long-term dependability and longevity.

Double Block And Bleed Valve

Double Block And Bleed Valve