{Handling exacting conditions of arctic implementations involves specialized valve mechanics. Our enterprise’s arctic 3-way orbital mechanism remedies are designed to provide steady work even at very low temperatures, typically below -150°C. These assemblies offer notable conveyance management in condensed fluids such as nitrogen, oxygen, and argon, frequently applied in arenas like LNG, research equipment, and hospital facilities. The specialists specialize in robust construction, including minimal-friction barrier components and careful fabrication, to confirm watertight activity. Contemplate the pros of upgrading your chilled system with our innovative 3-way ball instrument options.

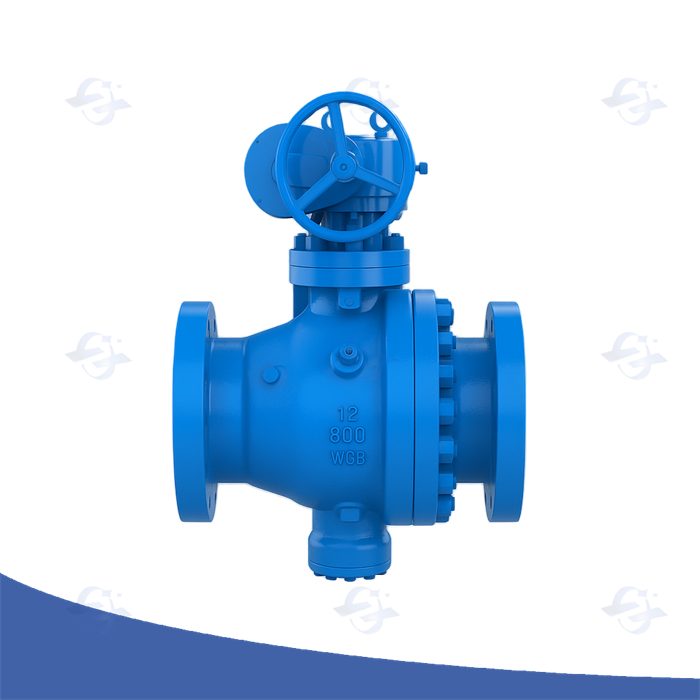

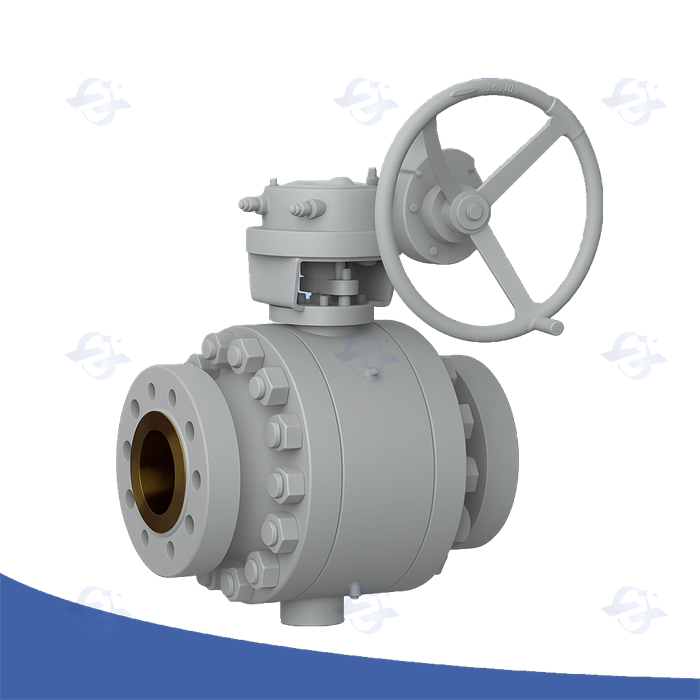

High-Performance Dual Block and Bleed Rotational Valve Packages

Concerning vital processes, particularly where outflow is restricted, leading double block and bleed valve units offer distinctive protection. This groundbreaking design incorporates two separate closure valve seals, in addition a bleed outlet, allowing for substantiation of the full shut-off and finding of any conceivable oozing. Regularly employed in mining procedures, synthesis treatment, and frost settings, these devices dramatically amplify functional protection and curtail the likelihood of ecological effect.

Tri-Path Glacial Orbital Mechanism Design

That generation of T-way icy circular tap presents a special engineering issue. These components are typically employed in key industrial tasks where drastic degrees must be upheld. Key considerations include element option, in particular regarding susceptibility at low coldness, and the imperative for airtight closure to inhibit seepage of cold substances. Elaborate examination techniques and meticulous production methods are needed to assure steady efficiency and lifespan under such challenging performance circumstances.

Cryogenic Actuator Function in Technical Applications

These demanding needs of chilly tasks, such as supercooled natural gas handling and cryogenic nitrogen storage, necessitate steady control device mechanisms. Integral block vent instruments provide a particularly robust and effective solution to achieving zero-leak barrier while facilitating frequent maintenance. Their design contains a primary assembly with a small drain channel, allowing controlled pressure expulsion during closure and resumption. This inherent aspect minimizes remaining substance entrapment, thereby ensuring unrivaled security and productivity even under the most tough performing locales. Furthermore, the ability to monitor bleed flow provides valuable inspection evidence for activity maximization.

Confirming 3-Way Globular Valve Fastening in Tough High-Pressure Applications

Achieving solid barrier performance with 3-way orbital valves becomes particularly critical when operating within marked pressure scenarios. The design should account for significant forces and potential escape of fluid pathways. Specialized elements, often including cutting-edge metals like durable steel or exotic alloys, are crucial to withstand the stringent conditions. Furthermore, advanced mounting geometries and exact formation processes are mandatory to minimize creep and guarantee a impenetrable link even under fluctuating tension cycles. Regular inspection and planned overhaul programs are also vital for endurance and unbroken operational efficiency.

Freezing Ball Valve Leakage Prevention Strategies

Decreasing "discharge" from cryogenic "sphere valves" demands a multifaceted "method". Initial "construction" considerations are paramount; material "choice" must account for extreme "coldness" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "ingredient", meticulous "development" processes – including stringent weld "surveys" and non-destructive "examination" – are vital to ensure structural integrity and eliminate voids that could become "routes". A "decisive" component is proper "arrangement"; thermal "contraction" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "maintenance" – including periodic "monitoring" for signs of wear and "rectification" of any identified issues – is indispensable for maintaining a reliable, leak-tight "fastening”. Ultimately, a robust "plan" incorporating these elements is necessary to ensure the safe and efficient "performance" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "reduction", safety "uncertainties", and costly "cessation”.

Double-Layer Block and Escape Device Evaluation Methods

For certifying the integrity and safety of critical piping frameworks, rigorous dual closure and purge tool assessment procedures are essential. These tests, often mandated by regulatory bodies and industry best principles, typically involve simulating simultaneous closure of two isolation valves while simultaneously ensuring the drain system remains functional and correctly discharges any trapped substance. A common mode is to utilize a pressure evaluation where the system is pressurized to its maximum working pressure, and the oozing rate around the closed valves is meticulously tracked. The escape system's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of evaluation results, including any discrepancies observed, is crucial for maintaining a reliable function.

Apprehending Overall Block Drain Component Performance

With the purpose to accurately oversee strain apparatuses, a comprehensive awareness of integral block discharge device efficiency is unequivocally indispensable. These dedicated devices mostly serve to successfully let out spare load from a assembly during certain employed levels. A common installation embraces a locked area combined to the central pressure source, letting one guided expulsion if mandatory. The intrinsic structure reduces the exposure of pressure overload, conserving both the machinery and the adjacent vicinity. Regular supervision and maintenance are vital to guarantee peak function.

Picking the Suitable 3-Way Ball Valve for Cryogenic Fluids

Selecting a appropriate 3-tri-ball apparatus for cryogenic functions demands careful scrutiny of several critical components. The extremely low freezes inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present peculiar challenges. Material option is paramount; only materials with proven matching and ductility at these temperatures, such as hardened steel grades like 304L or 316L, or specialized pure alloys, should be scrutinized. Furthermore, the tool's sealing proficiency is vital to prevent discharges, requiring innovative stem sealing configurations and low-temperature agents. Finally, pressure measures and actuation approaches, taking into account potential pressure spikes, must be attentively matched to the system's conditions. Neglecting these factors can lead to major failure and safety exposures.

Arctic Orbital Valve Substance Agreement Handbook

Selecting the appropriate element for cryogenic round valves is paramount, given the critical temperatures involved. This reference highlights common constituents and their response when exposed to cryogenic fluids such as solution nitrogen, cryogen helium, and oxygen. Stainless steels, particularly sorts 304 and 316, often demonstrate adequate durability and tarnishing resistance, though martensitic steels require careful consideration regarding brittleness. Aluminum alloys can be suitable for certain applications, however, their workability and immunity to specific chemicals needs comprehensive evaluation. Copper alloys, while offering some positives, may exhibit weakened capability at these lowered temperatures. Consultation with vendors and comprehensive evaluation is essential to verify permanence and reliability in cryogenic processes.

Increasing Twin Lock and Purge Setup Efficiency

Realizing optimal performance in double seal and release installations hinges on a multifaceted approach. Careful review of module selection is critical, with a focus on compound correspondence and force rating. Regular supervision of escape channels for obstruction is urgent, often entailing the use of precise monitoring apparatus. Furthermore, procedure advancement—including assessment of circulation rates and compression variation—can profoundly improve overall arrangement steadiness and security. Finally, alignment to creator guidelines and the execution of a comprehensive preservation routine are unavoidable for long-term performance and endurance.

integral block and bleed valve

integral block and bleed valve