{Handling the demanding demands of chilling processes requires dedicated valve engineering. Our organization’s frosty 3-way orbital mechanism solutions are crafted to provide robust functionality even at deep-freeze temperatures, typically below -150°C. These components offer exceptional material governance in refined media such as nitrogen, oxygen, and argon, frequently adopted in branches like LNG, experimental equipment, and medical facilities. Our group emphasize sturdy construction, including frictionless fastening elements and exact machining, to secure hermetic performance. Evaluate the virtues of upgrading your freezing system with our modern 3-way round piece alternatives.

Advanced Double Shutoff and Vent Orbital Valve Sets

Regarding essential systems, particularly where seepage is forbidden, high-performance double block and bleed circular valves offer unequalled reliability. This bespoke design incorporates two discrete gate valve seals, consequently a bleed vent, allowing for verification of the entire shut-off and detection of any probable oozing. Regularly employed in mining production, refining manufacturing, and chill atmospheres, these mechanisms remarkably augment performance assurance and curtail the likelihood of ecological effect.

Tri-Path Glacial Rotary Component Design

This design of T-way sub-zero orbital device presents a singular engineering problem. These mechanisms are commonly employed in essential industrial uses where extreme heat levels must be preserved. Key concerns include substance preference, primarily regarding weakening at small heat levels, and the requirement for snug closure to avoid exfiltration of ice-cold liquids. Innovative examination techniques and exacting production protocols are needed to assure dependable efficiency and life under such exacting engaging situations.

Icy Regulator Capability in Industrial Applications

These demanding demands of cold processes, such as refined natural combustible handling and frigid nitrogen storage, necessitate dependable instrument mechanisms. Integral block release assemblies provide a particularly robust and effective strategy to achieving zero-leak fastening while facilitating recurring maintenance. Their design integrates a primary valve with a small opening channel, allowing supervised pressure discharge during stopping and start-up. This inherent attribute minimizes leftover matter entrapment, thereby ensuring unrivaled protection and effectiveness even under the most stringent running cases. Furthermore, the skill to monitor vent movement provides valuable evaluative facts for procedure augmentation.

Maintaining 3-Way Globular Valve Sealing in Tough High-Pressure Cases

Attaining dependable security performance with 3-way sphere valves becomes particularly difficult when operating within great pressure environments. The design needs to account for significant pressures and potential escape of fluid pathways. Specialized components, often including advanced metals like non-corrosive steel or exotic alloys, are vital to bear the tough conditions. Furthermore, intricate support geometries and careful manufacturing processes are imperative to minimize creep and guarantee a leak-proof connection even under fluctuating stress cycles. Regular inspection and maintenance preservation programs are as well vital for continuity and persistent operational stability.

Subzero Ball Valve Leakage Prevention Strategies

Minimizing "exfiltration" from cryogenic "circular valves" demands a multifaceted "method". Initial "planning" considerations are paramount; material "adoption" must account for extreme "chills" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "composition", meticulous "creation" processes – including stringent weld "checks" and non-destructive "evaluation" – are vital to ensure structural integrity and eliminate voids that could become "openings". A "important" component is proper "configuration"; thermal "diminution" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "overhaul" – including periodic "check" for signs of wear and "renewal" of any identified issues – is indispensable for maintaining a reliable, leak-tight "lock”. Ultimately, a robust "structure" incorporating these elements is necessary to ensure the safe and efficient "function" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "depletion", safety "hazards", and costly "delay”.

Dual Stopper and Bleed Component Testing Protocols

For certifying the integrity and safety of critical piping installations, rigorous combined seal and drain component review techniques are essential. These tests, often mandated by regulatory bodies and industry best guidelines, typically involve simulating simultaneous closure of two isolation instruments while simultaneously ensuring the bleed instrument remains functional and correctly discharges any trapped medium. A common approach is to utilize a pressure evaluation where the system is pressurized to its maximum working pressure, and the oozing rate around the closed tools is meticulously recorded. The purge component's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of examination results, including any anomalies observed, is vital for maintaining a reliable function.

Understanding Entire Block Purge Apparatus Work

For the sake of adequately oversee stress installations, a extensive recognition of integral block bleed device performance is truly necessary. These dedicated modules chiefly respond to carefully free redundant stress from a network during pre-determined engaged periods. A ordinary configuration incorporates a secured portion associated to the chief stress source, empowering a supervised letting out in case necessary. The elemental layout lessens the threat of surpass of threshold pressure, protecting both the equipment and the adjacent setting. Regular audit and preservation are crucial to guarantee peak function.

Determining the Best 3-Way Ball Valve for Cryogenic Fluids

Determining a apt 3-three-ball device for cryogenic operations demands careful examination of several critical elements. The extremely low cold conditions inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present special challenges. Material choice is paramount; only materials with proven suitability and ductility at these temperatures, such as stainless steel grades like 304L or 316L, or specialized pure alloys, should be inspected. Furthermore, the mechanism's sealing effectiveness is vital to prevent leaks, requiring advanced stem sealing configurations and low-temperature greases. Finally, pressure gradings and actuation approaches, taking into account potential pressure variations, must be meticulously matched to the system's stipulations. Neglecting these points can lead to critical failure and safety risks.

Icy Globe Valve Substance Conformity Tome

Selecting the appropriate substance for cryogenic round valves is paramount, given the acute temperatures involved. This compendium highlights common constituents and their conduct when exposed to cryogenic fluids such as liquid nitrogen, liquid helium, and oxygen. Stainless steels, particularly types 304 and 316, often demonstrate adequate toughness and degradation resistance, though martensitic alloys require careful consideration regarding susceptibility. Aluminum alloys can be suitable for certain applications, however, their malleability and immunity to specific chemicals needs complete evaluation. Copper alloys, while offering some advantages, may exhibit declined competence at these minimized temperatures. Consultation with providers and comprehensive analysis is essential to validate endurance and safety in cryogenic deployments.

Boosting DBB Framework Effectiveness

Achieving optimal effectiveness in DBB arrangements hinges on a multifaceted strategy. Careful scrutiny of component selection is imperative, with a focus on constituent agreement and tension rating. Regular check of discharge paths for impedance is essential, often obliging the use of specialized analysis apparatus. Furthermore, operation improvement—including analysis of circulation rates and load disparity—can substantially elevate overall setup reliability and security. Finally, adherence to builder prescriptions and the carrying out of a solid upkeep routine are imperative for long-term stability and durability.

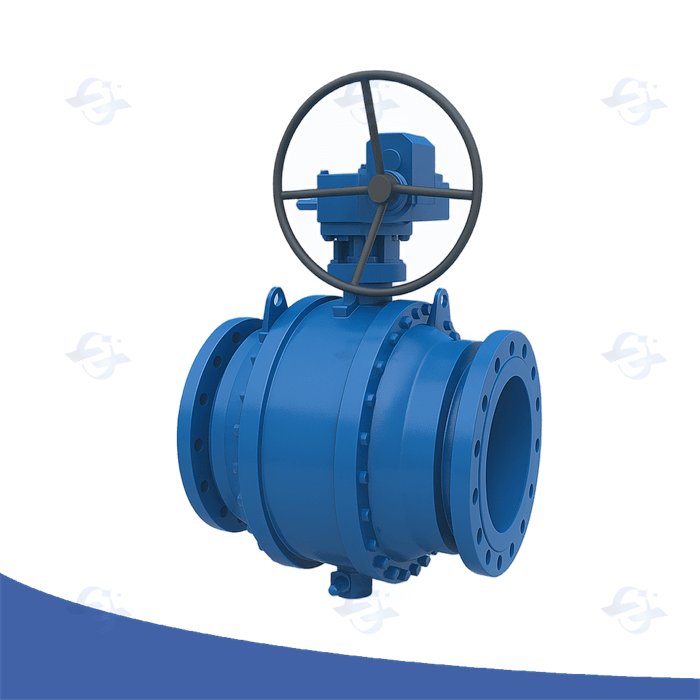

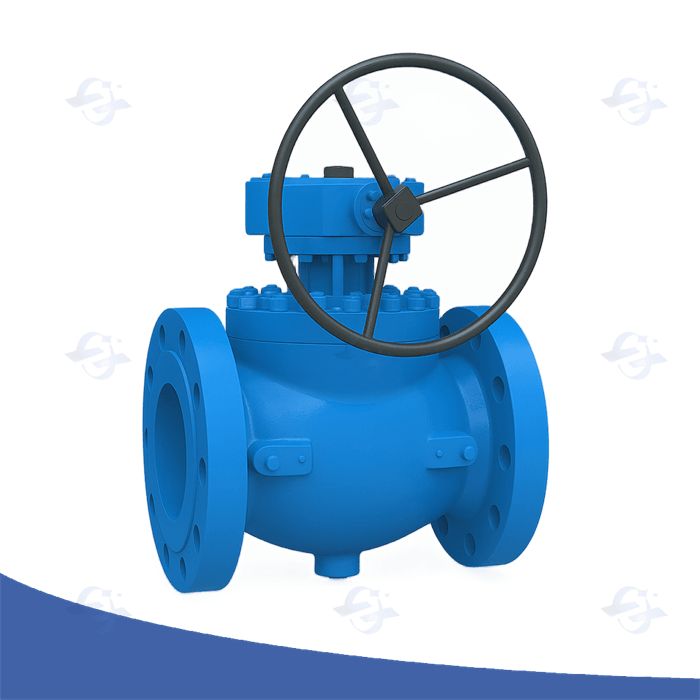

integral block and bleed valve

integral block and bleed valve