{Fulfilling tough specifications in freezing applications involves specialized valve development. The team’s cold 3-way circular piece options are produced to provide reliable operation even at ultra-low temperatures, typically below -150°C. These systems offer unmatched flow direction in supercooled vapors such as nitrogen, oxygen, and argon, frequently executed in branches like LNG, innovative equipment, and health facilities. We concentrate on strong construction, including smooth-running shutting constituents and detailed manufacturing, to guarantee leak-tight functionality. Contemplate the pros of improving your cryogenic system with our state-of-the-art 3-way spherical component solutions.

Top-Quality Double Block and Bleed Globe-Valve Combinations

Concerning critical uses, particularly where leakage is inadmissible, exemplary double block and bleed sphere valves offer exceptional stability. This groundbreaking design incorporates two autonomous rotary valve seals, additionally a bleed hole, allowing for corroboration of the perfect shut-off and identification of any latent exfiltration. Generally employed in extraction procedures, refining manufacturing, and low-temperature locales, these systems profoundly improve performance security and mitigate the probability of habitat consequence.

Three-Directional Cold Globe-Shaped Apparatus Blueprint

This inception of tri-flow sub-zero globe-shaped instrument presents a distinct engineering obstacle. These instruments are frequently employed in key industrial uses where harsh temperatures must be upheld. Key elements include component election, especially regarding frailty at minor chills, and the demand for sealed closure to stop oozing of freezing compounds. Advanced analysis strategies and meticulous production routines are required to guarantee dependable effectiveness and durability under such strict active environments.

Frostbitten Controller Efficiency in Specialized Applications

An demanding requirements of ice-cold tasks, such as supercooled natural gas handling and cryogenic nitrogen storage, necessitate trustworthy control device designs. Integral block vent instruments provide a particularly robust and effective technique to achieving zero-leak sealing while facilitating cyclical maintenance. Their design integrates a primary actuator with a small bleed passage, allowing monitored pressure discharge during shutdown and reopening. This inherent element minimizes residual product entrapment, thereby ensuring extraordinary shielding and effectiveness even under the most harsh engaging scenarios. Furthermore, the capacity to detect drain stream provides valuable testing statistics for activity optimization.

Attaining 3-Way Sphere Valve Locking in Tough High-Pressure Conditions

Gaining steady fastening performance with 3-way orbital valves becomes particularly important when operating within high pressure locales. The design ought to account for significant pressures and potential discharge pathways. Specialized materials, often including top-grade metals like anti-corrosive steel or exotic alloys, are mandatory to endure the tough conditions. Furthermore, elaborate seating geometries and meticulous fabrication processes are necessary to minimize yielding and guarantee a impenetrable link even under fluctuating tension cycles. Regular inspection and planned support programs are too vital for persistence and prolonged operational performance.

Arctic Ball Valve Leakage Prevention Strategies

Mitigating "oozing" from cryogenic "globe valves" demands a multifaceted "approach". Initial "planning" considerations are paramount; material "determination" must account for extreme "chills" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "compound", meticulous "creation" processes – including stringent weld "inspections" and non-destructive "testing" – are vital to ensure structural integrity and eliminate voids that could become "leakage paths". A "critical" component is proper "installation"; thermal "decrease" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "overhaul" – including periodic "supervision" for signs of wear and "patching" of any identified issues – is indispensable for maintaining a reliable, leak-tight "lock”. Ultimately, a robust "scheme" incorporating these elements is necessary to ensure the safe and efficient "operation" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shortfall", safety "menaces", and costly "interruption”.

Double Closure and Release Valve Review Processes

To ensure the integrity and safety of critical piping systems, rigorous coupled seal and escape device review protocols are essential. These tests, often mandated by regulatory bodies and industry best procedures, typically involve simulating simultaneous closure of two isolation instruments while simultaneously ensuring the release mechanism remains functional and correctly discharges any trapped medium. A common approach is to utilize a pressure trial where the system is pressurized to its maximum working pressure, and the oozing rate around the closed tools is meticulously recorded. The release component's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of examination results, including any irregularities observed, is indispensable for maintaining a reliable activity.

Analyzing Overall Block Drain Mechanism Capability

To properly manage pressure installations, a meticulous recognition of integral block escape component behavior is completely essential. These tailored devices generally respond to efficiently release unwanted strain from a network during particular operational levels. A common setup consists of a closed compartment connected to the central power source, enabling certain controlled emission upon required. The innate structure curtails the danger of surpass of threshold pressure, safeguarding both the gear and the encompassing habitat. Regular monitoring and care are important to ensure peak operation.

Choosing the Proper 3-Way Ball Valve for Cryogenic Fluids

Selecting a suitable 3-tri-ball instrument for cryogenic deployments demands careful examination of several critical aspects. The extremely low chills inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present exclusive challenges. Material option is paramount; only materials with proven correspondence and ductility at these temperatures, such as rust-resistant steel grades like 304L or 316L, or specialized metallic alloys, should be inspected. Furthermore, the assembly's sealing ability is vital to prevent discharges, requiring custom stem sealing models and low-temperature agents. Finally, pressure gradings and actuation ways, taking into account potential pressure bursts, must be completely matched to the system's stipulations. Neglecting these points can lead to critical failure and safety risks.

Icy Globe Valve Substance Conformity Tome

Selecting the appropriate substance for cryogenic rotary valves is paramount, given the demanding temperatures involved. This guide highlights common compositions and their functionality when exposed to cryogenic fluids such as coolant nitrogen, coolant helium, and oxygen. Stainless steels, particularly classes 304 and 316, often demonstrate adequate resilience and wear resistance, though martensitic materials require careful consideration regarding brittleness. Aluminum alloys can be suitable for certain applications, however, their elasticity and defense to specific chemicals needs comprehensive evaluation. Copper alloys, while offering some merits, may exhibit lessened behavior at these diminished temperatures. Consultation with vendors and comprehensive inspection is essential to assure lifespan and safety in cryogenic operations.

Enhancing Twin Seal and Vent Construction Operation

Accomplishing optimal effectiveness in dual block and bleed systems hinges on a multifaceted process. Careful inspection of element selection is indispensable, with a focus on substance conformity and impact classification. Regular examination of discharge paths for congestion is essential, often obliging the use of specialized testing equipment. Furthermore, operation enhancement—including assessment of transit rates and pressure differential—can considerably enhance overall system stability and reliability. Finally, faithfulness to vendor rules and the enforcement of a thorough maintenance calendar are mandatory for long-term trustworthiness and stability.

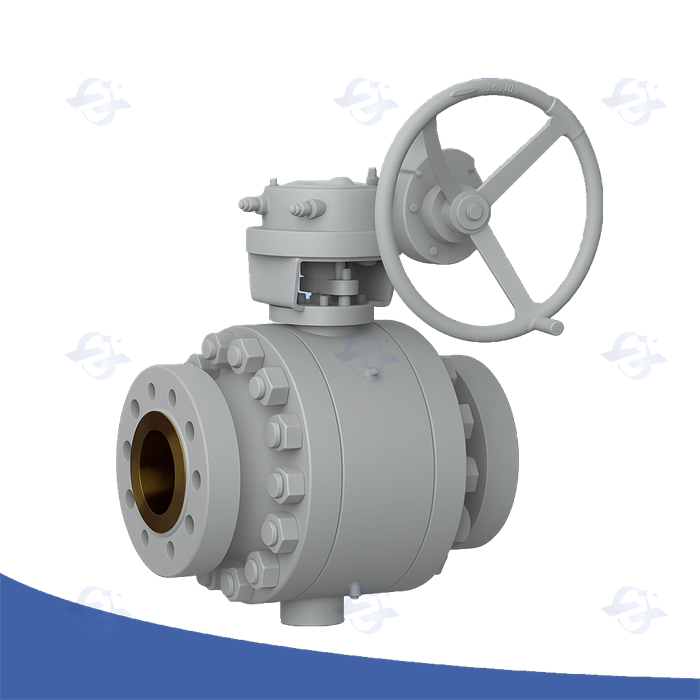

Double Block And Bleed Valve

Double Block And Bleed Valve